TUNGSTEN WIRE BASKETS, PKG/10

Tungsten Wire Baskets

The tungsten boats, baskets and filaments are manufactured from high grade tungsten. Of all metals pure form, tungsten has the highest melting point (3422°C / 6192°F), the lowest vapor pressure at temperatures above 1650°C (3000°F) and has the highest tensile strength. Tungsten also has the lowest coefficient of thermal expansion of any pure metal. This combination of properties makes tungsten the ideal material for evaporation sources. During evaporation, it can alloy with some materials such as Al or Au. In this case, another evaporation source material should be used such as alumina coated boats or baskets. Other materials useful for evaporation sources are molybdenum and tantalum. Please see the Deposition Techniques Table for extensive information on vacuum deposition and suitability of evaporation sources.

Tungsten Wire Baskets

Tungsten Wire Baskets

Tungsten Wire Baskets

Tungsten Wire Baskets

Tungsten Wire Baskets

Tungsten Wire Baskets

Tungsten Wire Baskets

3-Strand Tungsten Wire Basket, 5 coils, 3/4" x 1/4"

3-Strand Tungsten Wire Basket, 5 coils, 1/2" x 3/16"

3-Strand Tungsten Wire Basket, 4 coils, 5/8" x 1/4"

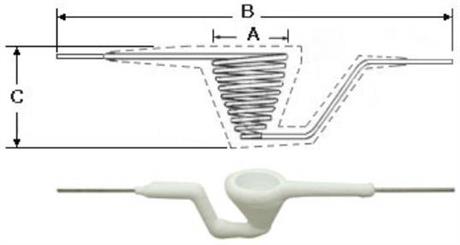

The Alumina coated tungsten evaporation basket is an efficient design which acts as an internally heated crucible. The ceramic coated evaporation baskets for vacuum evaporation have the distinct advantage that they require relatively low power (63 to 768 W) to reach a temperature of 1475°C (high enough to evaporate Ni in high vacuum). This will enable many researchers to experiment with thermal evaporation who only have access to low cost, low power evaporation supplies. The closed side crucible form allows to use pallets, grains, wires or even powders as evaporation material for upwards evaporation applications. Molten metal evaporants are contained as an induction propelled spinning ball inside the cavity. Most materials can be completely evaporated without loss to the crucible. A broad range of evaporation materials can be used in these alumina coated sources: Au, Ag, Pd, In, Sn, Sb, Bi, Cd, Cu, Pb, Zn, Co, Ni, Fe, Mn and alloys such as Nichrome and Permalloy. Maximum temperature for this type of alumina coated tungsten basket should not exceed 1800°C. There are 6 different types of baskets available with a top opening ranging from 0.15" to 0.90".

| Prod. No. / Style | Volts | Amps | Watts | Temp | Wire Dia. | "A" Top I.D. |

Inside Depth |

"B" OAL |

"C" Height |

Vol cm³ |

| 84-21 Style 1 | 5.70 | 11 | 63 | 1475°C | 0.020" | 0.150" | 0.225" | 4" | 0.375" | 0.021 |

| 84-22 Style 2 | 6.20 | 40 | 248 | 1475°C | 0.040" | 0.375" | 0.350" | 4" | 0.500" | 0.21 |

| 84-23 Style 3 | 6.90 | 39 | 272 | 1475°C | 0.040" | 0.420" | 0.425" | 4" | 0.575" | 0.32 |

| 84-24 Style 4 | 13.00 | 33 | 429 | 1475°C | 0.040" | 0.790" | 0.725" | 3-1/4" | 0.875" | 1.92 |

| 84-25 Style 5 | 7.00 | 50 | 350 | 1475°C | 0.050" | 0.500" | 0.775" | 4" | 0.925" | 0.83 |

| 84-27 Style 6 | 15.80 | 49 | 768 | 1475°C | 0.050" | 0.900" | 0.975" | 4" | 1.125" | 3.36 |

Style 4, Alumina Coated Tungsten Wire Basket, ID 0.790", 429 Watts

Style 6, Alumina Coated Tungsten Wire Basket, ID 0.900", 768 Watts

Style 5, Alumina Coated Tungsten Wire Basket, ID 0.500", 350 Watts

Style 2, Alumina Coated Tungsten Wire Basket, ID 0.375", 248 Watts

Style 3, Alumina Coated Tungsten Wire Basket, ID 0.420", 272 Watts

Style 1, Alumina Coated Tungsten Wire Basket, ID 0.150", 63 Watts

The tungsten boats, baskets and filaments are manufactured from high grade tungsten. Of all metals in pure form, tungsten has the highest melting point (3422°C / 6192°F), the lowest vapor pressure at temperatures above 1650°C (3000°F) and has the highest tensile strength. Tungsten also has the lowest coefficient of thermal expansion of any pure metal. This combination of properties makes tungsten the ideal material for evaporation sources. During evaporation, it can alloy with some materials such as Al or Au. In this case, another evaporation source material should be used such as alumina coated boats or baskets. Other materials useful for evaporation sources are molybdenum and tantalum. Please see the Deposition Techniques Table for extensive information on vacuum deposition and suitability of evaporation sources.

Tungsten Filament, 6 Coils, 1/8"ID

Tungsten Filament, 8 coil, 3/8"ID pkg/5 $45.30 Qty: 1

Tungsten Filament, 10 coil, 1/4"ID

Tungsten Filament, 10 coil, 1/16"ID

Tungsten Filament, 4 coil, 3/16"ID

Tungsten Filament, 6 Coils, 1/4"ID

3-Strand "V" Filament

Tungsten Filament, 6 Coils, 3/16"ID

Tungsten Filament, 4 coil, 3/16"ID

Tungsten Rod Source, 4" L

1-Strand "V" Filament

Tungsten Boat - Al2O3 barrier, 5/8" x 1-3/4" trough

Tungsten Boat, 1/2" x 1-1/2" trough

Tungsten Boat, 1" x 2-1/8" trough

Tungsten Boat- Al2O3 barrier, 1/4" x 3/4" trough

Tungsten Boat, Narrow Trough, 1/4" x 1/8" x 3/4" trough

Tungsten Boat, Alumina coated, 1/2" dimple

Tungsten Boat, 1/2" x 1-1/2" trough

Tungsten Boat, Narrow Trough, 1/4" x 1/8" x 1-1/2" trough

Tungsten Boat, Narrow Trough, 1/4" x 1/8" x 3/4" trough

Tantalum directional Boat Source, 3" x 1/4"

Molybdenum Covered Boat Source, 1-7/8" x 3/4", hole on one side

Molybdenum Covered Boat Source, 1-7/8" x 3/4", hole on-axis

Tungsten Boat, 5/8" x 1" trough

Tungsten Boat, Small, 7/16" x 1/8" dimple

Tungsten Boat, 3/8" x 1/2" trough

Tungsten Boat, Small, 7/16" x 3/32" dimple

Tungsten Boat, Small, 7/16" x 1/8" dimple pkg/5 $38.70 Qty: 1

Tantalum Directional Boat Source, 1-7/8" x 1/4"

Tungsten Boat, Small, 3/16" x 1/16" dimple

Tungsten Boat, Small, 3/8" x 1/16" dimple

Tungsten Boat, Small, 3/8" x 1/8" dimple